Structural composition

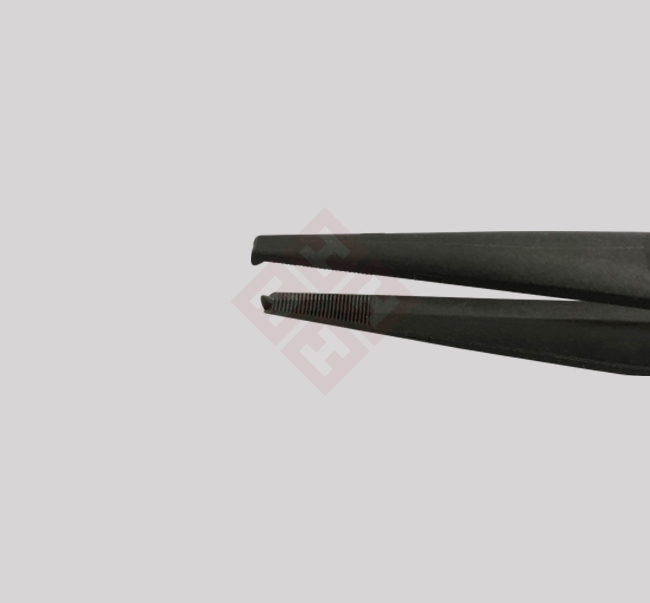

Forming parts: determine the shape of tweezers, etc., composed of core, cavity, commonly used P20 and other high-quality die steel, cutting, wear resistance and other properties.

Pouring system: including the main channel, diverter channel, gate, cold hole, the role is to connect the injection molding machine, guide the melt, control the flow rate, collect cold material.

Cooling system: The mold is provided with a water channel, and the circulating water is used to dissipate heat, so that the tweezers can cool quickly and ensure the uniform temperature of the mold.

Design essentials

Parting surface: Choose in the largest contour, avoid holes, grooves, do not affect the appearance of performance.

Gate: Select the right type and position according to the tweezers, such as side gate can reduce the weld mark.

Cooling system: reasonable arrangement of the water channel to ensure uniform temperature, complex tweezers or need special cooling.

Manufacturing process

Roughing: CNC machine tools to spare, for finishing.

Finishing: Precision and surface quality are guaranteed with high-precision equipment.

Surface treatment: nitriding, hard chrome plating, improve mold performance, prolong life.

Assembly and debugging: assembly after cleaning and deburring, adjust the mold, check the problem and repair.