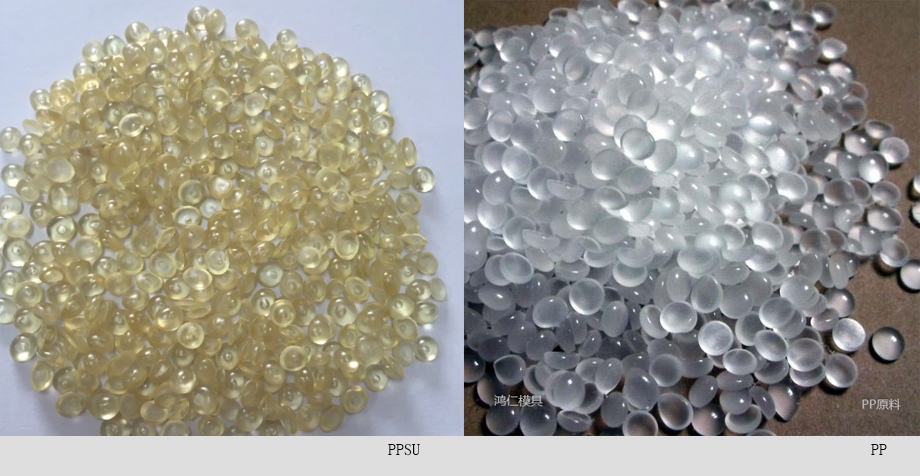

The difference between PPSU and PP materials

PPSU (polyether sulfone polymer) and PP (polypropylene) are two different types of plastic materials that have different chemical structures and physical properties. Here are some of the main differences:

Chemical structure: PPSU is a high-performance thermoplastic made from styrene, ethylene glycol and sulfur dioxide monomers by

polymerization. PP is a thermoplastic prepared by polymerization of propylene monomer.

Physical properties: PPSU has a higher melting point and glass transition temperature, so it has higher high temperature resistance.

Its chemical resistance is also very good, can withstand the influence of strong solvents, acids, alkalis. PPSU also has good impact

resistance, fatigue resistance and low water absorption. In contrast, the thermal stability and chemical resistance of PP are slightly

worse than that of PPSU.

Applications: Due to its excellent heat, chemical and mechanical properties, PPSU is commonly used in the manufacture of

components requiring high temperature and chemical resistance, such as automotive parts, aerospace components, medical devices

and industrial equipment. PP is often used to manufacture a variety of plastic containers, food packaging and disposable items.

Molding method: PPSU and PP are thermoplastics, often using injection mold injection molding, and PP in addition to injection

molding, can also be used for extrusion molding.

In general, PPSU has higher performance and durability compared to PP, but also correspondingly higher price. Therefore, when

selecting materials, decisions need to be made according to the requirements and budget of the specific application.